GEORAM® ENGINEERED AGGREGATE PIERS (EAP)

WHAT ARE ENGINEERED AGGREGATE PIERS (EAP)?

Engineered Aggregate Piers (EAP) are a cost-effective solution to foundation support on soft soil sites and provide an excellent alternative to deep piles/caissons and over-excavation and replacement filling.

EAP are densely compacted aggregate piers that improve the soils in which they are installed. The piers are constructed with specialized ramming equipment in pre-drilled cavities (usually 18"-36" diameter) and can resist both compression loading and uplift forces.

The piers can range from 5' to 25' in length and typically achieve an improvement in soil bearing capacity ranging from 6,000 to 10,000 psf. With the use of casing, EAP can be constructed below ground water in all soils ranging from peat to loose clean sands to soft clays.

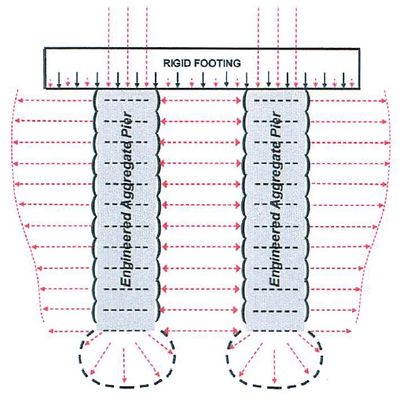

The combination of constructing the piers in pre-excavated cavities and the lateral stress build-up that results from the specialized ramming equipment, are the key elements that set the EAP apart from other pier or stone column systems.

WHEN TO USE THE GEORAM® EAP SYSTEM

The GeoRam® EAP system should be considered:

- Where over-excavation and replacement is required.

- When deep foundations such as piles or caissons are required.

- Where settlement control is essential.

- In earthquake-prone areas

- On sites with restricted access or overhead.

- For building additions and expansions.

- For poorly compacted fill, debris fill, and organic fill

The GeoRam® EAP system is applicable in any situation where a significant increase in stiffness and/or shearing strength of a soil mass will improve engineering performance. This includes:

- Spread footings -- Increase in bearing capacity and reduction of settlement

- Floor slabs/mats -- Improve subgrade uniformity and reduce settlements

- Slopes -- Increase in factor of safety for stability

- Excavations -- Increase in temporary support

Note the significant lateral stress increase in the soils surrounding the EAP element. THIS is the key to the incredible success of Engineered Aggregate Piers have in reducing settlement in soft soils.

WHY CHOOSE THE GEORAM® EAP SYSTEM?

The GeoRam® EAP foundation system has a long, proven track record of providing foundation cost savings; superior, unmatched settlement control; and high design bearing pressure for footings. Cost savings can come from:

- Concrete savings from reduced footing sizes

- Elimination of pile caps and grade beams

- Elimination of the need to overexcavate and re-compact fill

- Ability to earth-form Engineered Aggregate Pier-supported spread footings

- Reduction in project schedule due to speed of GeoRam® EAP installation

- After pier installation is complete, the site is left clean, neat and ready for footing excavation

- No surprises. Once the GeoRam® EAP system has been installed, uncertainty has been eliminated

HOW ARE GEORAM® EAP CONSTRUCTED?

The construction process for Engineered Aggregate Piers is project friendly in terms of simplicity, speed, cost, and reliability.

EAP are constructed in a pre-excavated cavity with specialized ramming equipment that imposes significant lateral pre-stress into the undisturbed soils surrounding the element.

The combination of constructing the piers in pre-excavated cavities and the lateral stress build-up that results from the specialized ramming equipment, are the key elements that set EAP apart from other aggregate pier or stone column systems. They are the primary factors accounting for the phenomenal success in controlling foundation settlements in soft soils.

Pier cavities are typically excavated by conventional drilling techniques, using either truck-mounted auguring equipment or "dangle drill" equipment mounted on an excavator or crane.

Drilled cavities for EAP elements typically range from 18" to 36" in diameter.

With the use of casing, EAP elements can be constructed below ground water in all soils ranging from peat to loose clean sands to soft clays.

Aggregate used for pier construction is typically high quality crushed rock, such as used for highway base course construction. Lower quality aggregate can be used so long as compacted characteristics are relatively uniform and are defined by field testing. For liquefaction mitigation, free-draining aggregate can be used so the pier element also functions as a drain to relieve excess pore water pressures.

EAP are constructed in lifts of about 1 to 2 foot thickness (depending on ramming energy used), with each lift rammed vertically and laterally using the specialized tamper. Within 15 seconds of tamping, a lift can receive over two times the compactive energy that is put into the maximum density laboratory test (ASTM 1557).

Since EAP elements are constructed in pre-excavated cavities, there is essentially no remolding of the surrounding soils, as occurs with other stone column techniques that involve complete soil displacement. Hence, with the EAP technique the surrounding soils cannot experience strength loss due to the construction methods, but rather gain a significant increase in stiffness as each lift of aggregate is rammed. Other aggregate pier systems can not achieve this level of stiffness increase!

By constructing EAP elements in clusters spaced from about 1½ to 3 diameters apart, the GeoRam® reinforced soil mass experiences significant permanent pre-stressing, which greatly improves its strength and consolidation characteristics (extending several feet beyond the outside piers). Hence, the so-called "group effect" is very desirable for the GeoRam® system because it improves performance (whereas, in the design of pile foundations the group effect is normally avoided because it tends to reduce individual pile capacities).

FAQ ABOUT THE GEORAM® EAP SYSTEM

Q: What is it about GeoRam EAP that constitutes a Value Engineering Technology?

A: GeoRam engineering represents a viable, verifiable foundation technology in-between deep and shallow foundations. GeoRam Engineered reinforcement was developed to take maximum advantage of soil's unique engineering behavior.

Q: What are some examples of these conditions?

A: Soft, fine-grained soils, loose, coarse-grained soils, poorly-compacted fill soils, debris or organic fill soils, and peat.

Q: What other special uses for GeoRam Engineered reinforcement have proven to be highly effective in addition to settlement control for buildings?

A: (1) High Capacity uplift anchors. Columns with over 400 kip uplift loads have been supported by Engineered Aggregate Pier anchor elements.

(2) Landslide stabilization.

(3) Retaining walls, highway embankments, bridge approaches

(4) Slabs on-grade.

(5) Storage silos.

(6) Tunnel system reinforcement and pavement stabilization.

Q: What equipment is used for constructing EAP elements?

A: GeoTech Foundation Company - West performs complete design and build of the GeoRam system utilizing its own equipment. One GTFC-West crew is typically comprised of a drill rig (truck mounted or dangle drill), one excavator with the specialized tamper attached to the energy source, and one skid steer for moving aggregate. If pier cavities require casing in order to keep the holes open, then a fourth piece of equipment is added.

Downloads

Engineered Aggregate Pier Specification (pdf)

Download